Our Services

Our complete services bring innovative concepts to life, covering every stage of the process from initial product development and raw material production to intelligent manufacturing and final product delivery.

Certifications

ISO 9001:2015 | IATF 16949:2016 | Critical to Quality Inspections

Product Design and Innovation

Private Labelling

We help private label brands to create innovative products and gain an edge over their competitors. You can take advantage of a manufacturer with over 20 years of experience, leaving the product management to us, and invest in ready-to-sell goods customized with your branding.

Award-Winning and Patented Design

Our award-winning designs showcase our commitment to exceptional design and innovation. We are honored by the recognition we have received from the Red Dot Design Award, which inspires us to continue delivering products that meet the highest standards of quality, aesthetics, and functionally, leaving a lasting impact.

We also prioritize intellectual property protection and strive to ensure that our products are 99% patented in terms of appearance, uses, and functions. We proudly possess a total of 73 combined Patents for innovation, utility and design.

Innovative Concepts

Starting with idea generation, we create innovative concepts that undergo validation and market research to assess feasibility. The selected ideas are then further developed and refined through design, prototyping and testing. We aim to create products that meet market demand and fill the gaps in the market.

Technical Expertise

We integrate technical know-how into the design process, which allows us to identify potential problem areas and add engineer values into your product. This proactive approach helps us avoid subsequent adjustments, resulting in faster design time.

Engineering and Development

CAD/CAM Product and Mold Drawing

Our designer and engineer work in conjunction to bridge the gap between design and production. We facilitate the process through visualizing 2D or 3D models of their designs and creating detailed drawings of the products and molds. These models are then used to generates instructions for machines and equipment to manufacture the product.

DFM & Part Analysis

We carefully evaluate and analyze to provide engineering advice on material selection and product configurations, with a focus on fitness-for-purpose, tooling feasibility and producibility. This enables us to enhance productivity and minimize production risks.

Moldflow Analysis

We stimulate the molding process to anticipate and address potential issues, allowing us to further refine parts and mold design before finalizing the drawings.

Precision Tooling

-

CNC

High-efficiency CNC machines available to cut molds of any types for any raw materials.

-

EDM

High-accuracy EDM machines available to handle any type of molds with multiple cavities with high surface complexity and low specifications variations tolerance.

Optimal Efficiency and Precise Accuracy

High-Performance Tooling

Equipped with Makino CNC and EDM machines, we deliver precise and efficient molding solutions for multi-component molding, LSR injection molding, silicone rubber compression molding, and Injection Stretch-Blow Molding (ISBM). These advanced technologies allow us to create highly accurate and intricate products while optimizing our production processes.

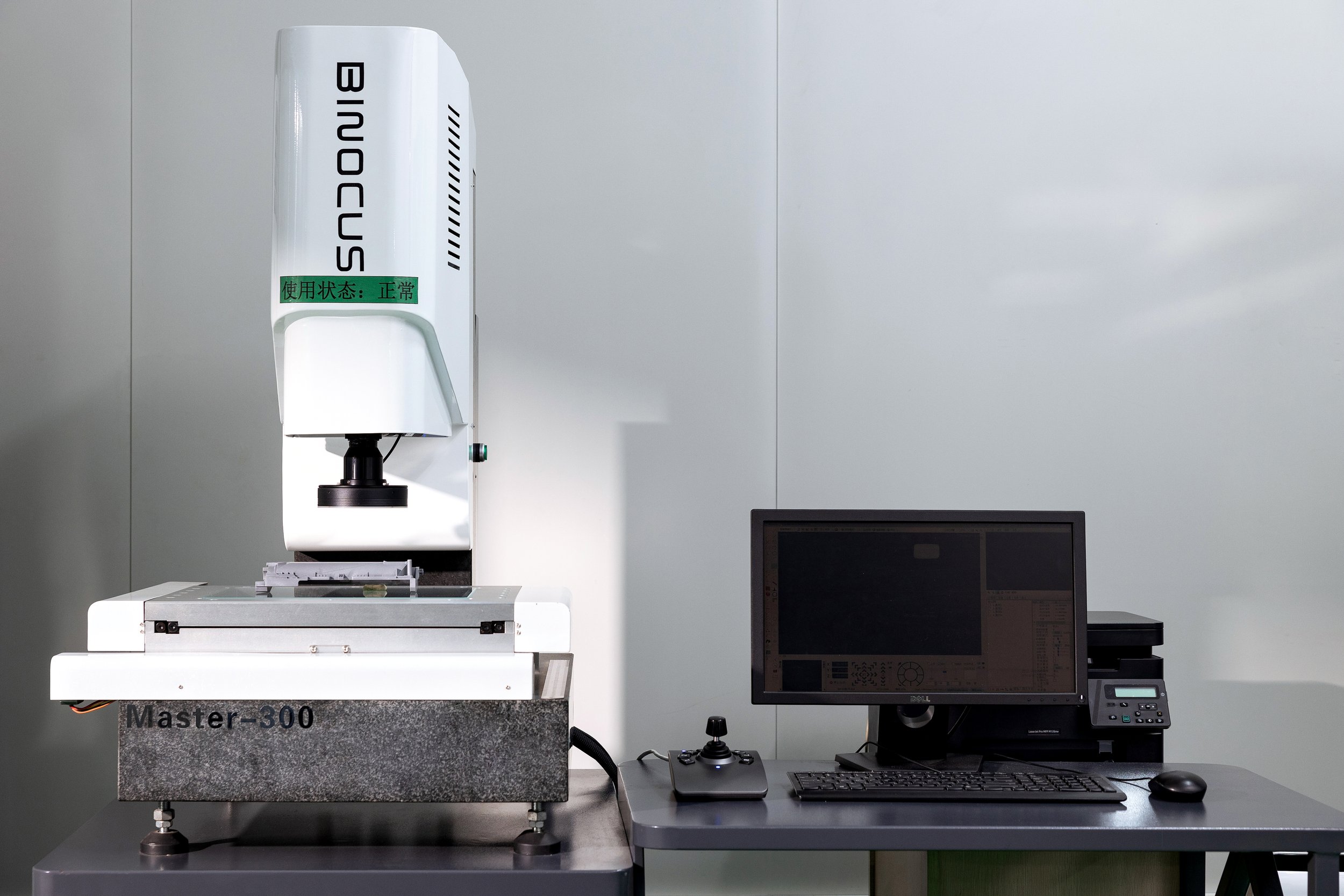

Mold Laboratory

At Homepin, our mold laboratory is equipped with highly precise equipment to ensure that mold measurements and dimensions align precisely with product specifications, maintaining the highest quality standards.

-

2D Measuring Instruments

We utilize 2D measuring instruments to validate that parts and products to be manufactured comply with product specifications and regulatory requirements. With meticulous precision, these instruments ensure that every component meets the exacting standards set forth by your designs.

-

3D Scanners

Our 3D measuring instruments capture the geometric structures of molds, enabling us to inspect and identify any deviations from their 3D models. This technology ensures that the molds are flawlessly replicated, leading to consistent and superior product outcomes.

Mold Maintenance

We take a proactive approach to mold maintenance, conducting regular inspections, cleaning, and repairs to ensure their optimal performance. This minimizes the risk of unexpected breakdowns, maximizes production uptime, and guarantees the timely delivery of high-quality products to our valued customers.

Raw Material

Research and Testing

With a focus on sourcing and innovating silicone and rubber raw materials for application with other sustainable materials, we carefully design compound formulations to facilitate the desired properties of the raw materials and the intended application of the final products. Additionally, we adopt various testing methodologies contributing to raw material improvements.

Upper and Auxiliary

Central Batching Systems

We are equipped with advanced Upper and Auxiliary batching systems that enable precise measurement of raw materials, additives, fillers, and other compounding components, ensuring efficient and accurate distribution and dispersion.

High-Speed Kneading Machines

Mixing Mill

Mixing and Compounding

Utilizes specialized high-speed kneading machines and mixing millers to achieve a consistent and well-blended quality of compound. To prevent premature or pre-cure of the silicone raw material, the curing agent compounding process is conducted in controlled cooling room.

Self-Sufficiency

We achieve self-sufficiency through in-house raw materials production, providing essential compounding ingredients and components, such as additives, agents and chemicals for raw material production. With an integrated supply chain, we secure control over critical ingredients, mitigating shortages and ensuring manufacturing stability and cost-efficiency.

Intelligent Manufacturing

Unique Molding Expertise

With expertise in various molding techniques, such as compression molding, injection molding, extrusions molding, and 1-stage injection stretch-blow molding (ISBM), we have the flexibility to provide on-demand molding solutions, and accommodate different materials and product specifications.

Automation and Robot Assistance

Advanced Technology

Equipped with advanced equipment, machinery and automated production systems to streamline production. Robot assistance could be found throughout our production facilities, particularly in plastic injection molding and 1-stage ISBM molding. This advanced-technology approach has a significant impact on reducing production costs, assuring product quality and increase productivity and production safety.

Quality Inspections

Certifications and Registrations

Our compliance mindset sets the foundation for our long-term and sustainable operations. Homepin is certified with ISO 9001, IATF 16949, and GMP, as well as FDA, LFGB, REACH, and RoHS registered. We always strive to match our quality systems with international standards to ensure we could well serve our customers from all around the world.

International Quality Standards

In-House Laboratories

To achieve the desired product properties and comply with international standards, we have a comprehensive array of testing equipment in our in-house laboratories. These advanced instruments are compatible with various tests, including VOC (Volatile Organic Compounds), pull force, flow speed, aging, humidity, oil resistance, heat resistance, adhesive resistance, heavy metals, oxidation, pressure, and more.

End-to-End Support from Concept to Production

Get in touch with a custom quote

Our team will reach out with a tailored quote and guide you through every step—from initial concept development to full-scale production management.