High-Precision OEM & ODM Silicone Rubber and Plastics Manufacturing

From Concept to Market, Faster and Smarter

Certifications

ISO 9001:2015 | IATF 16949:2016 | GMP | BSCI | Sedex | GSV | CTPAT | Management & Security

Trusted By Global Brands

Explore Our Products

Creating exceptional products involves a dedicated process and meticulous attention to every detail.

Home & Kitchen

Baby & Toddler

On The Go

About Homepin

Founded in 2001, Homepin is a leading national high-tech enterprise specializing in silicone, rubber, and plastic product solutions. We integrate product design, advanced material research and development, precision mold manufacturing, and intelligent production to deliver comprehensive, one-stop solutions for our clients.

We have world-class solutions in precision tooling, compression molding, injection molding, extrusion molding, and 1-stage injection stretch blow molding (ISBM) with over-molding capabilities.These technologies position Homepin as one of the most versatile and competitive manufacturers in the industry.

Our products are widely used across diverse sectors, including maternal and infant care, houseware, outdoor living, 3C medical assessories, household appliances, new energy vehicles, and footwear. We are a trusted strategic partner for globally recognized brands such as Gree, Midea, Hisense, NARWAL, SKG, IKEA, OXO, Blue Box, Infantino, Wolverine, and Timberland.

Quality Management

Security & Social Responsibility

Our Complete Services

We support every stage of the product creation process, from research and design to manufacturing and logistics.

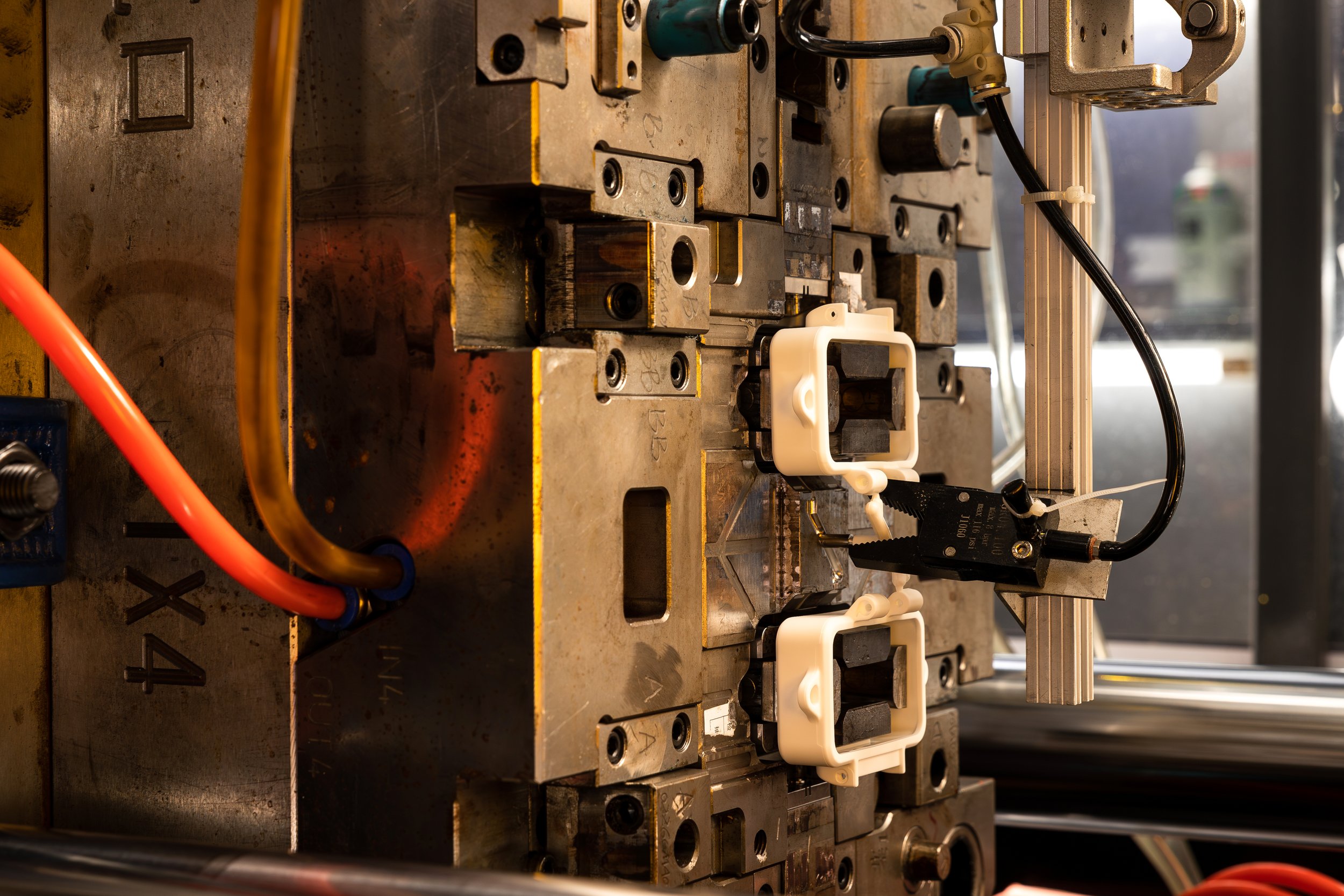

High-Accuracy Molds for Scalable Production

Precision Tooling Solutions

Our in-house tooling department is the foundation of our production quality. Equipped with state-of-the-art CNC and EDM machines, we create high-precision, custom molds tailored for silicone, rubber, plastic, and more.

From Concept to Creation

Product Design & Engineering Solutions

We transform ideas into tangible products through thoughtful design and expert engineering. Our process begins with innovative concept generation backed by market research and validation. We guide you through material selection, product configuration, and functional optimization—delivering innovative, manufacturable solutions tailored to your goals.

Scalable, Reliable, and Quality-Driven Production

High Precision Manufacturing Solutions

We adopt high-automation manufacturing approach that ensures consistency, accuracy, and exceptional quality. Whether for small production runs or large-scale orders, our advanced machinery and experienced team deliver product meets exact specifications and performs reliably in real-world use. With a streamlined process from raw material to finished product, we uphold strict quality standards, support scalable production, and meet the unique requirements of various industries.

Our Capabilities

We are dedicated to constantly improving and diversifying our capabilities to meet the evolving needs of the industry and provide innovative solutions for our clients.

We provide custom silicone compression, injection, and extrusion molding services. Our expertise extends to silicone over-molding with other components and materials.

Combining advanced technology and industry-recognized experience, we offer manufacturing solutions in rubber compression, injection and extrusion molding.

Leveraging robot-assisted plastic injection molding and 1-stage injection stretch blow molding (ISBM), we achieve high automation, productivity, and consistent quality.

Trusted By Global Brands

End-to-End Support from Concept to Production

Get in touch with a custom quote

Our team will reach out with a tailored quote and guide you through every step—from initial concept development to full-scale production management.